Trade fair preview 28.09.2022

Recovered Carbon Black from used tires

600,000 tons of used car tires are disposed of in Germany every year. Worldwide, around 1.8 billion used tires are disposed of every year. Up to now, the used tires have been recycled for raw materials and energy: “The used tires are mainly fed into the cement industry for thermal recycling. The industrial Carbon Black contained in the car tires is rarely recycled”, explains Martin Schwarz, Head of Application Lab Plastics & Rubber at Brabender.

The production of one ton of Carbon Black (CB) requires 1.5 tons of fossil raw materials and a lot of water. In addition, the production of Carbon Black generates up to three tons of carbon dioxide. These emissions of environmentally harmful gases and the use of raw materials can be reduced by simply recycling the Carbon Black contained in old tires.

Protecting the environment: recycling old tires

An ordinary car tire contains about three kilograms of carbon black. Carbon Black (CB) can be recovered from tires using a process known as pyrolysis: “The tire is exposed to 600 to 700 degrees Celsius and pyrolysis oil, recovered Carbon Black (rCB) and ash, which consists of silica and zinc oxide, among other things, are recovered”, says Schwarz.

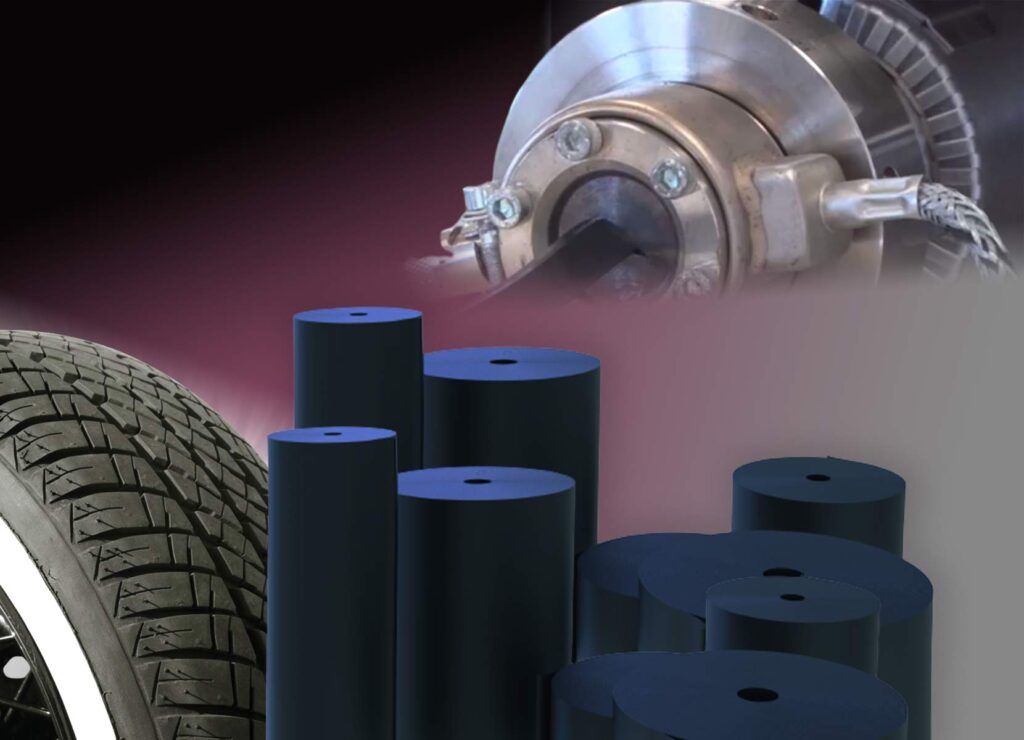

Brabender offers solutions for the recycling of recovered carbon black from scrap tires and for the tire industry in general. As a manufacturer of measurement and process technology on a laboratory scale, the company develops, produces and sells devices and equipment worldwide for testing material quality in the plastics and rubber industries. This includes equipment for determining the properties of rubber or recovered Carbon Black.

Brabender Absorptometer C can determine oil number of Carbon Black

The Brabender Absorptometer C can be used to determine process properties. The oil number measured with the instrument can be used to determine the structure of Carbon Black and other powdered products such as silica. On the basis of this, conclusions can be drawn about the quality of the product manufactured with Carbon Black, since the oil number is directly related to the processing and vulcanization properties. The oil number is determined according to ASTM D 2414, ASTM 3493 (Carbon Black).

Brabender’s Internal mixer 350 SX with intermeshing blades can also be used in the tire industry to produce rubber compounds. The metering mixer was designed for use in the rubber and caoutchouc industry. It is suitable for recipe development in the rubber industry and, like most of Brabender’s equipment, makes a major contribution to sustainability, as material can be saved in rubber production by identifying quality losses via simulation of the process on a laboratory scale.

More information on Brabender’s recycling applications will be available at the K trade fair in Düsseldorf from October 19 to 26. In hall 10 at booth A14 the Brabender team is waiting and will be pleased to help.