Brabender:

CuttingDevice

- Easy integration: control and logging of knife speed via the software

- Compact: optimal dimensions for laboratory operation

- Flexibile: Knife holder extenable from 4 to 8 knifes, hence higher cutting frequency

- Hygienic design: Easy access to the parts to be cleaned

- Safety: Zero position of the knife does not stop directly in front of the die

The cutting device is designed for Brabender single- and twin-screw extruders and thus for laboratory operation. It can be used, for example, to trim snack or feed extrudates to a specified length after they exit the die. The gap between the cutting knives and the die can be precisely adjusted with just one handle.

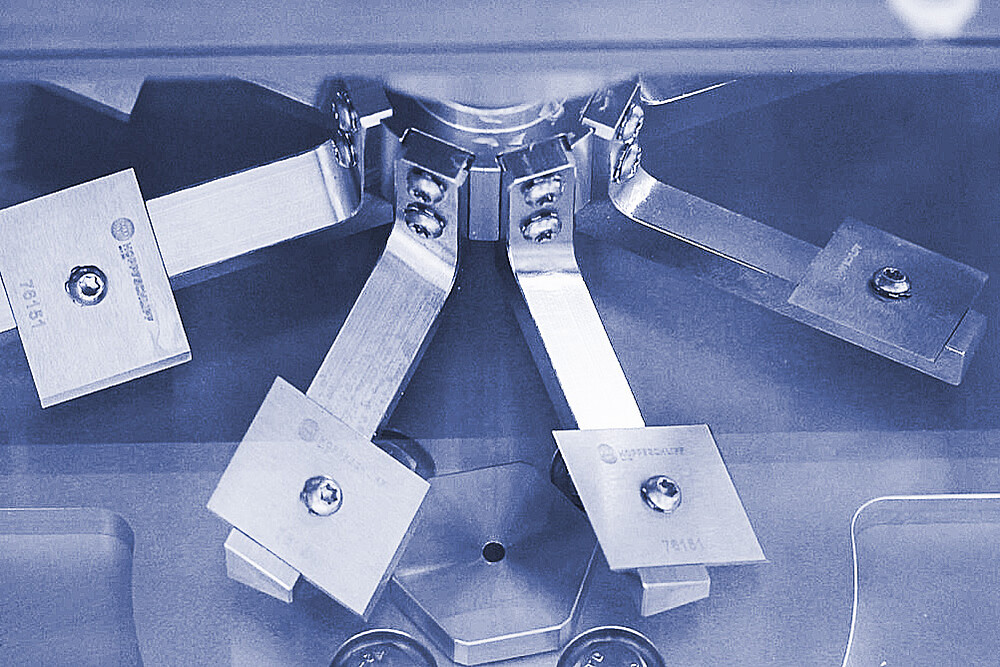

The new blade geometry now consists of a blade holder that can be optionally equipped with 4 or 8 blades, depending on the application and the desired cutting frequency. When using 4 blades, 4,500 cuts per minute can be achieved, with 8 blades 9,000 cuts (1125 rpm per blade).

Per manual creep speed it can be observed if blades have been fixed correctly and rotate accordingly. For additional safety, the zero position of the blade holder has been adjusted so that no blade can stop directly in front of the die.

The wider cutting blades (19 mm) can be easily replaced when worn.

The cutting process can be continuously observed via a Plexiglas pane in front of the cutting chamber. After the cut, the extrudates down into a container provided for this purpose. The cutting chamber allows easy access to the parts to be cleaned after the test.

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Brochure | Cutting Device Brochures

Compatible instruments

Brabender:

Extruder / Extrusiograph 19/25 and 19/32

Brabender:

Extruder/Extrusiograph 30/25 and 30/32

Brabender:

Measuring Extruder and Grooved Extruder 19/20

Brabender:

Mini-Compounder KETSE 12/36

Brabender:

Single-Screw Extruder 19/25

Brabender:

Stand-Alone Extruder KE 19

Brabender:

Stand-Alone Extruder KE 30