Standard Starch Viscometer:

Brabender Viscograph-E

- Starch-testing device compliant with ICC and AACCI

- Analysis with globally recognized Brabender Units

- Temperature determination directly at the sample

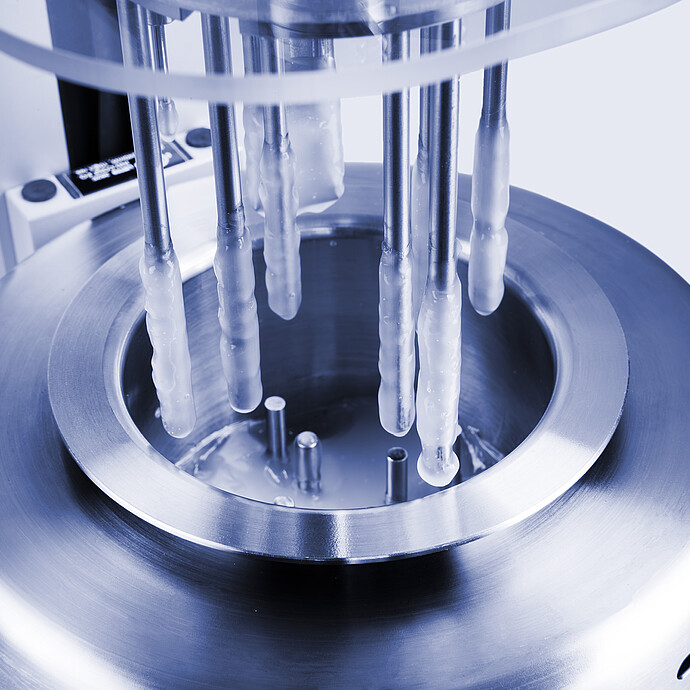

- No disposables: Reduce waste due to stainless steel parts

- See and share data with MetaBridge from any device at any time

Ensure compliance with Viscograph-E, a standard starch viscometer that measures the gelatinization properties of starch according to ICC and AACCI. Real-time quality monitoring through reference curves and precise temperature measurements enhance accuracy, while a 40 g sample size guarantees homogeneity and minimizes errors. The durable stainless steel beaker and stirrer design is resistant to wear and tear and ensures precision over the instrument’s lifetime, letting you avoid follow-up orders associated with disposable systems. Streamline operations with our MetaBridge software, which enables remote access, multi-instrument connectivity, and integration with third-party systems.

Key features

Rely on our market-leading expertise

Know your using an instrument from the established market leader in the flour and starch measurement field. This means communication in the universal language for flour and starch analysis, Brabender Units (BU), which reduces complexity and increases collaboration.

Ensure compliance with your standard starch viscometer

The Viscograph-E is the leading instrument on the market for testing starch while complying to the main national and international standard for gelatinization properties stated in ICC and AACCI.

Real-time temperature monitoring means better products

The temperature probe of the Viscograph-E has direct contact with the sample. In contrast to conventional devices, this ensures measurement of real sample temperatures without temperature fluctuations. This leads to highly precise results reflecting real-life production conditions.

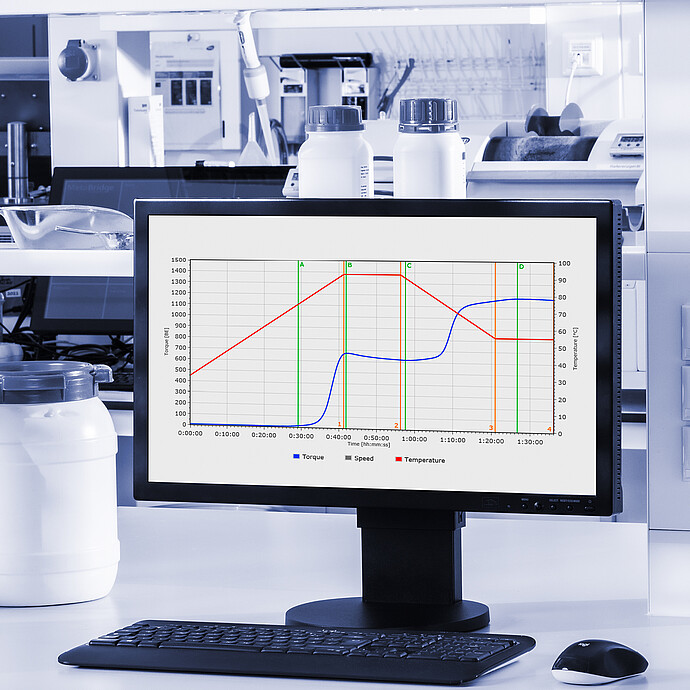

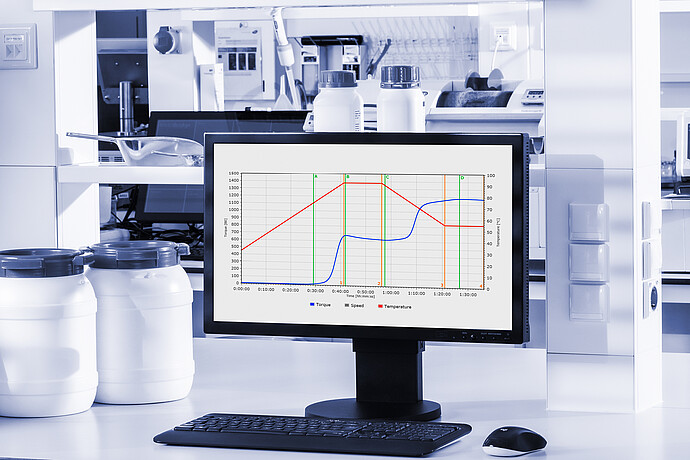

Use MetaBridge for better data collaboration

MetaBridge, the intuitive software tailored to Brabender devices, simplifies the implementation of standards. With it, you can access measurements from any device and connect multiple instruments. You can also share data between teams and extend it to third-party systems (e.g., LIMS). By using reference curves, you can monitor material quality in real time.

A starch viscometer designed for accuracy and the long haul

The Viscograph-E has been designed with accuracy in mind. Its 40 g starch sample size reduces the impact of weighing errors and improves sample homogeneity. The stainless steel beaker and stirrer increase measurement accuracy and reduce repeat orders compared to disposable systems. You can also self-calibrate the standard starch viscometer with specific starches to extend its lifespan.

Technical specifications

| Mains connection | 230 V; 50/60 Hz + N + PE; 2.8 A 115V; 50/60 Hz + PE; 5.6 A |

| Heating rate | Standard: 1.5 °C/min Adjustable: 0.1 °C/min to 3.0 °C/min For special applications: Up to 4.0 °C |

| Sample volume (approx.) | Starch: 450 mL / flour 50 mL |

| Speed | 0 min-1 to 300 min-1 |

| Dimensions (W x H x D) | 560 mm x 890 mm x 430 mm |

| Weight | Approx: 30 kg |

Standards

AACCI

CRA

GB/T

ICC

ISI

LS/T

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Brochure | Viscograph E Brochures

Similar products

Accessories & Software

Accessories & Software

Accessories & Software

Accessories & Software

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.

Brabender:

ClimateLogger

- Checks and records the ambient conditions for each measurement

- Automatic data transfer to Brabender MetaBridge

- Insensitive to dust and moisture

- Multi-year battery durability

Software for Brabender Devices:

MetaBridge

- The benchmark for intuitive but comprehensive software

- Connect devices: seamless data flow, zero transcription errors

- Access results from any device at any time

- An array of standards and predefined methods, just a click away

- Export data to third-party systems and share with colleagues