Brabender:

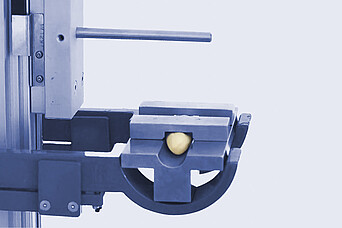

Extensograph-E

- Standardized: Comparability through ISO, AACC and ICC

- Accurate: Determination of the rheological optimum for the best baking result

- Fast: Flexibility through adaptable short methodsFlexible: Available in “micro extensograph” version for small sample volumes

- MetaBridge software: user-guided workflows, reference limits, measurement correlations, customizable methods & parameters and much more

- Connectivity: Support for third-party solutions (ERP, LIMS)

On the basis of the recorded extensogram, reliable information on rheological dough properties – and therefore later baking results – can be determined. Recognize and determine the effects of flour additives, such as for example enzymes or ascorbic acid, and flexibly adapt the short methods to your own particular application.

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

Accessories

Accessories

Accessories

Accessories

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.

Brabender:

ClimateLogger

- Checks and records the ambient conditions for each measurement

- Automatic data transfer to Brabender MetaBridge

- Insensitive to dust and moisture

- Multi-year battery durability

Brabender:

Micro Extensograph

- Small sample size

- Quick retrofit

- Higher flexibility