Lab- and Pilot-Scale Twin Screw Extruders:

TwinLab

- Compact extrusion solution with integrated drive

- Flexible: six different dosing options

- High shear energy: 1.43 OD/ID ratio

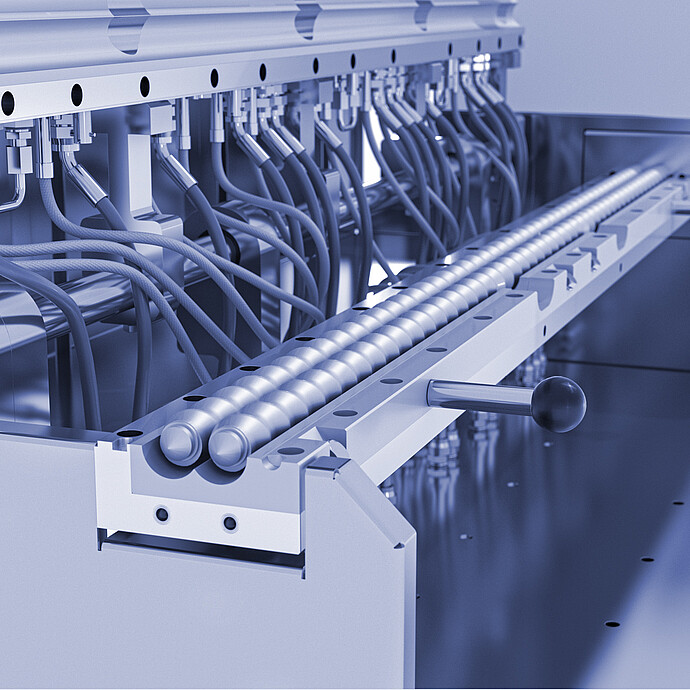

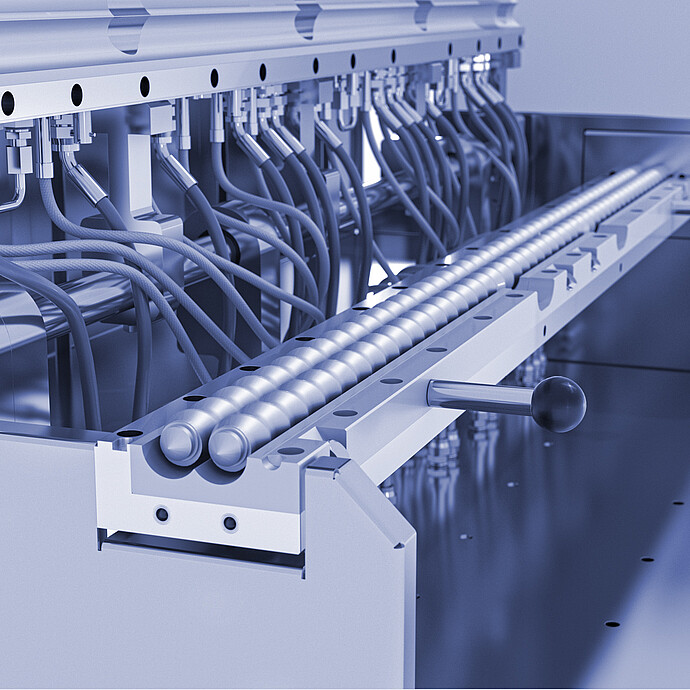

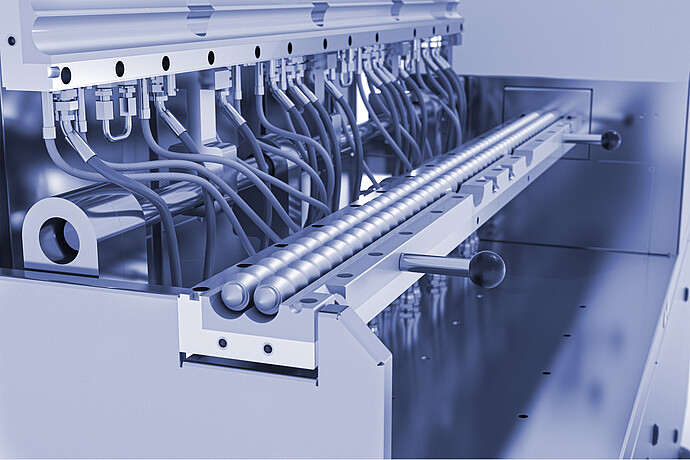

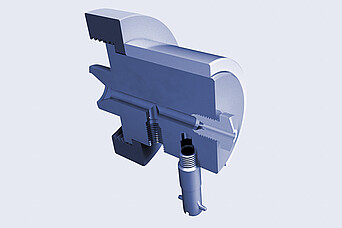

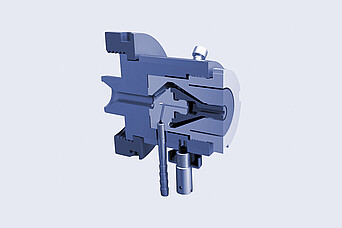

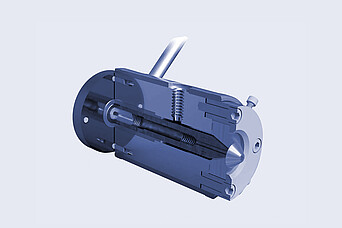

- Patented liner removal for easy cleaning

Experience the future of lab extrusion with the Brabender Twin Screw Extruders – the TwinLab series – which provides various configurations to process everything from liquids to pellets. Streamline your material testing for lab and pilot-scale setups, and optimize your extrusion production process. MetaBridge operating software ensures intuitive device control, paired with comprehensive features and data analytics. It lets you access data from any device at any time. TwinLab’s smart clam shell design makes the liner easy to access and clean. The modular TwinLab series is powered by the MetaStation drive unit and offers twin- and single-screw extrusion as well as batch-wise mixing.

Key features

Gain insights with lab-scale extrusion data

Our Twin Screw Extruders – the TwinLab series – are measuring extruders for lab and pilot scale that provide comprehensive diagrams with recorded measurement parameters, letting you gain a deeper understanding of the materials you're working with. Every step of the process is tracked and recorded, giving you insights into the characteristics of the extruded materials. This lets you adapt parameters, recipes, and configurations with pin-point accuracy, and reduces setup times and sample waste.

Measure results across platforms for better collaboration

Our MetaBridge operating software offers cross-platform access to measuring results, letting you access your recorded data from any device and location. This translates into maximum operator convenience and no transcription errors. You can easily export and provide data to colleagues and third-party systems and even send measuring data per email directly from the extruder. You can measure the following crucial parameters in the extrusion process:

- Temperature

- Pressure

- Torque

- Drive load

- And more…

Working in tough environments? Need easy cleaning? No problem

Our steel alloys for liners, screws, and dies have been designed to cope with abrasive applications. They can withstand temperatures above 500 °C. Whether you're working with highly corrosive or highly abrasive substances, our alloy will provide the durability you need. Because of the patented clam shell design with split and openable liners, you can easily monitor your screw configuration and processes as well as clean the screws and liners easily. This lets you keep your instrument clean and well-maintained – even in tough and abrasive applications.

Stay flexible with extruders of various sizes

Leverage extruders in various sizes and throughputs to meet your specific needs. Our range of extruders covers low and high-power applications. With throughputs ranging from 0.05 kg to 100 kg per hour, we cater to R&D labs and pilot scale production.

Modular extrusion solutions from a single supplier

The full Brabender twin-screw extrusion line solution is a modular plug-and-play system that combines extruders, feeders, pumps, dies, and downstream equipment. This means you get a complete extrusion line from a single supplier with a single point of contact, minimal setup costs, and quick startup time. Our modular extrusion solutions are powered by MetaStation drive units and let you easily switch between twin-, single-screw extrusion, and batch-wise mixing, all while providing the full spectrum of measuring parameters and analysis options of the stand-alone extruders. So even if you have limited space or budget, extrusion and mixing is accessible for you.

Your partner for special applications, customized solutions

Based on decades of experience in extrusion and vast application know-how, we find solutions where others don’t. We test your material and provide tailored solutions. With our in-house production and a dedicated R&D team, we even develop and supply customized solutions for all kinds of specific applications. Don’t hesitate to contact us in order to discuss your requirements and to find a customized solution for your extrusion task.

Technical specifications

| B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40 | |

| Screw diameter | 12 mm | 20 mm | 20 mm | 30 mm |

| L/D | 36 | 40 | 40 | 40 |

| Max. speed | 1200 rpm | max. 200 rpm (MetaStation 8 / 8E), with gearbox max. 800 rpm max. 400 rpm (MetaStation 16), with gearbox max. 1200 rpm | 1200 rpm | 1200 rpm |

| Max. screw torque | 2 x 15 Nm | 2 x 40 Nm | 2 x 40 Nm | 2 x 150 Nm |

| Max. power | N/A | N/A | 9.5 kW | 39 kW |

| Connectivity | Compatible with all MetaStation drive units | Compatible with MetaStation 8/8E and 16 drive units | Stand-alone unit | Stand-alone unit |

| Power supply | Fixed connection, supply via drive unit | Fixed connection, supply via drive unit | 3 x 400 V, 50/60 Hz + N + PE, 63 A; 3 x 230 V, 50/60 Hz + PE, 76 A | 3 x 400 V, 50/60 Hz + N + PE, 118 A |

| Dimensions (W X H X D) | With coaster: 1240 mm x 600 mm x 1300 mm Without coaster: 1240 mm x 600 mm x 450 mm | 2000 x 500 x 1565 mm | 2013 x 450 x 1566 mm | 2310 x 500 x 1590 mm |

| Weight | 175 kg (with support frame) | 420 kg | 480 kg | 850 kg |

Standards

ASTM

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Burger Elegance: Innovative Extrusion with Alternative Proteins Application Reports

-

Extrusion of Pulses for the Production of Meat Analogues Application Reports

-

Measurement of PVC Melt Viscosities by Torque Rheometer Application Reports

-

Brochure | Twin Screw Extruders Brochures

Accessories & Software

Accessories & Software

Accessories & Software

Accessories & Software

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.

Brabender:

Blown Film Take-Off Unit

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- User-friendly: Working height, winding torque and cooling air adjustable via touchscreen

- Application versatility: Adaptable to different film dimensions and properties

- Expandable: Measure and control film width and analyze film quality using optional modules

- MetaBridge Connect: Full control and automated data transfer to Brabender MetaBridge extruders

Brabender:

Conveyor Belt

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- Adjustable height

- Continuously adjustable speed

Brabender:

Film-Blowing Die Head

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- spiral mandrel distributors

- uills with easily exchangeable inserts

Brabender:

Filtratest

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- Quick change of sieves with drawer system

- Integrated pre-heating of the sieve package

- Short-time cycle times

- continuous extrusion procedure by bypass option of the melt flow

- Comfortable Windows Software

- Option: sliding funnel combination for flushing ring and sample

Brabender:

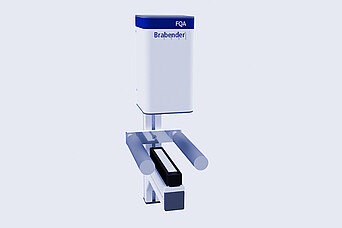

FQA Film Quality Analyzer

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- Versatile: Identification of different defect types

- Efficient: Automatic evaluation according to size classes

- Continuous: Quality inspection in the running process

- Flexible: Suitable for laboratory systems and production use

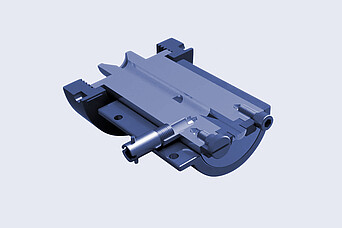

Brabender:

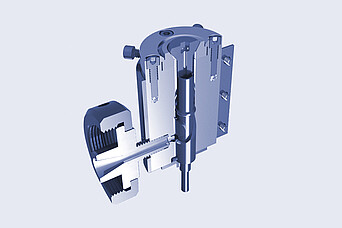

Modular Cooling Die

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- The modular design allows producing textures of different sizes

- Independent temperature control of three heating / cooling zones along the die

- Comprehensive process control through 6 openings along the die for material measurements (e.g. pressure, temperature)

- Addition of further product dimensions through modular design at a later stage possible

- Individual adaptation of the entire nozzle dimension according to customer’s requirements

Brabender:

Multi Strand Die

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- Increase the extrusion output

- two-strand die or a four-strand

- different ranges of strand diameters

Brabender:

Pasta Die Head

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- can be cooled with both air and water

- for pasta and similar products

Brabender:

Pelletizer

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- Uniform pelletizing

- Variable pellet sizes: stepless adjustment of positioning and outfeed speed

- Various pellet lengths

- Low-noise operation

- Simple loading

- Operated manually or via PC

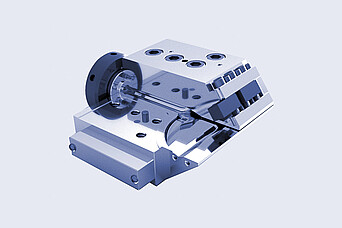

Brabender:

Rheometric Round Capillary Die Head

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- Continuous operation

- Coverage of the occurring shear rate range

- Accurate viscosity and shear rate data with the corresponding corrections calculated by the software

- All acquired values are suitable to evaluate the shear and thermal stability of your material

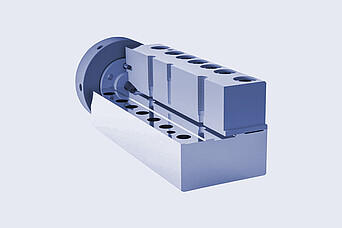

Brabender:

Rheometric Slot Capillary Die Head

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- Continuous operation Coverage of the occurring shear rate range

- Accurate viscosity and shear rate data with the corresponding corrections calculated by the software

- All acquired values are suitable to evaluate the shear and thermal stability of your material Requests

Brabender:

Ribbon Die Head

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- suitable for applications in plastics, rubber, food, and feed

- flexibility in terms of the belt thickness and width

- special geometries available on request

Brabender:

Round Strand Die Head

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- equipped with a heating collar

- diameter of 1 mm to 7 mm

- can be equipped with a cutting device

Brabender:

Swelltest

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- Calculation of the swell value

- High-precision, non-contact measurement

- Continuous diameter measurement

- With diagram printout

Brabender:

Tubing Die Head

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- easily exchangeable die inserts

- for different diameters and material strengths

Brabender:

Univex

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- Excellent film quality

- High take off speed

- Accurate temperature conditioning

Brabender:

Vertical Forced Feeder

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- Small sample sizes

- Compact

- Easy to clean

Brabender:

Water Bath

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- Adjustable height

- With overflow valve

Brabender:

Winder

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- Flexible and easy retrofitting of roll to belt haul off or vice versa

- Supports for various types of coils

- Precise setting of the haul off speed

- Adjustable distance between haul off and oscillating unit

- Ergonomic control panel

Brabender:

Wire Coating Die Head

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- different diameters are possible

- wire production line on a laboratory scale

- Wrap wires with polymer coatings

Brabender:

Wire Take-Off Unit

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- With Waterbath

- With CAN Bus

Software for Brabender Devices:

MetaBridge

TwinLab B-TSE-A 12/36 | B-TSE-A 20/40 | B-TSE-S 20/40 | B-TSE-S 30/40

- The benchmark for intuitive but comprehensive software

- Connect devices: seamless data flow, zero transcription errors

- Access results from any device at any time

- An array of standards and predefined methods, just a click away

- Export data to third-party systems and share with colleagues